Gears in Motion - Unlocking Mechanical Marvels

Gears, the unsung heroes of machinery! These toothed wonders are like the teenage sidekicks of the engineering world – often overlooked, but secretly doing all the heavy lifting. Let’s dive into the gear-y details, shall we?

What are gears?

Gears are toothed mechanism used to transmit rotational motion and power between driving mechanism (e.g. motor) and the driven part (e.g. wheels). They are crucial for:

- Changing rotational speed

- Adjusting torque

- Changing direction of motion

- Synchronizing rotational movement

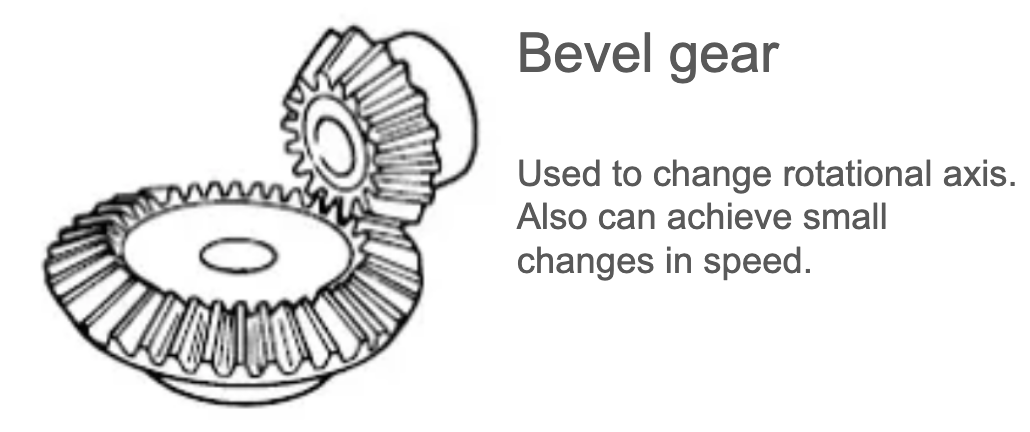

Types of gears

Some commonly used gears are described below.

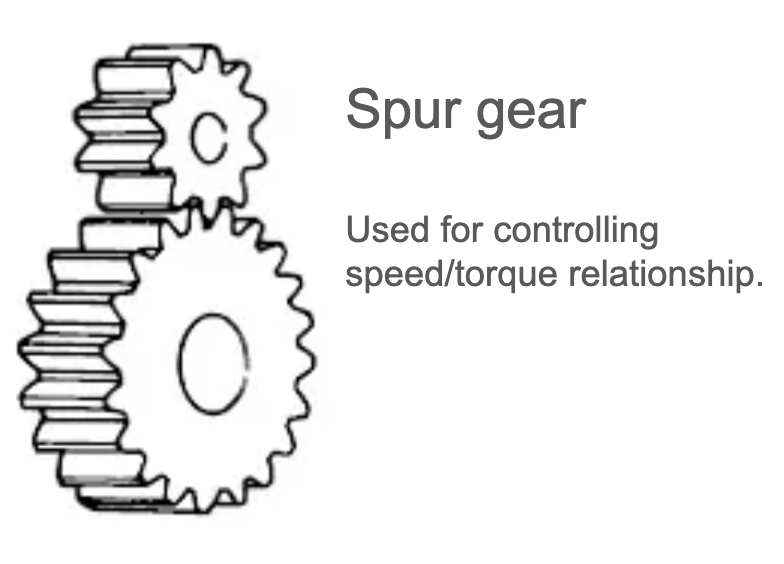

Spur Gears

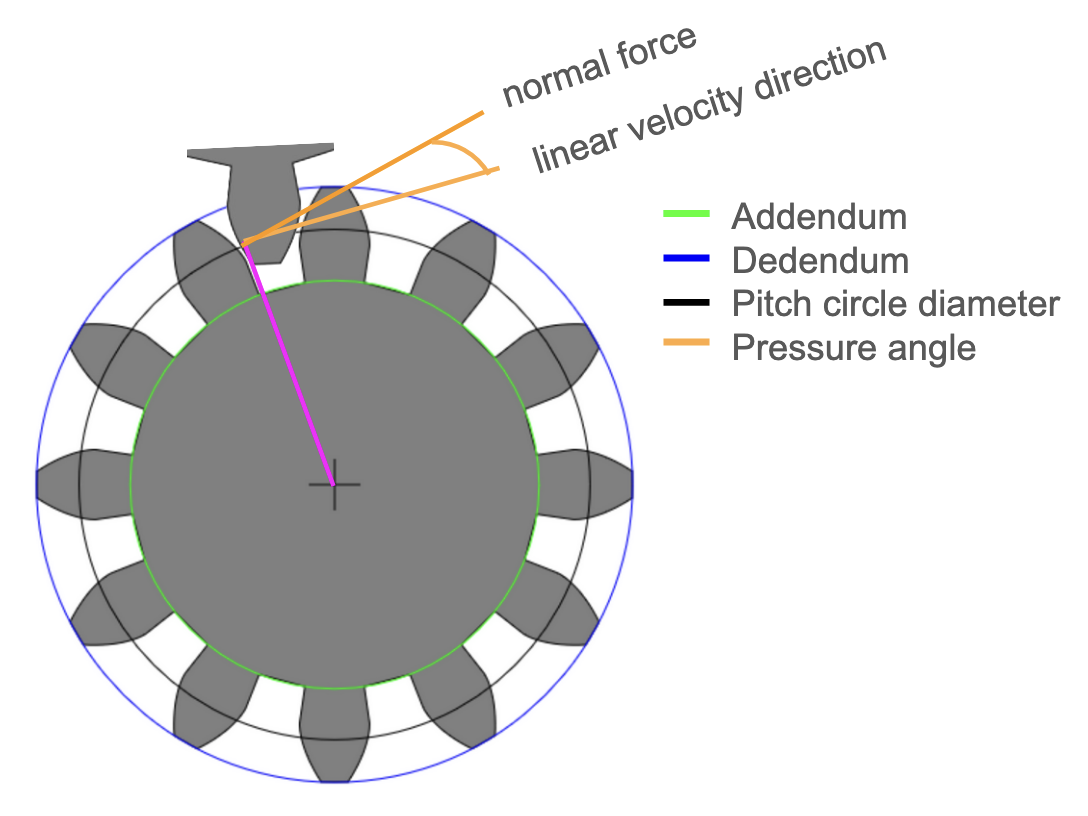

The spur gears are the most commonly used gears. Let’s understand them in detail. There are three things to decide for each gear.

-

Reference diameter or Pitch circle diameter: It is chosen based on geometry, torque and speed requirements. It decides how large the gear will be. -

Pressure angle: It is usually 14.5 deg or 20 deg (most common). -

Module: It determines the gear strength and load bearing capacity. Incresing module increases tooth thickness and strength, whereas reducing module increases the number of teeth giving smoother transmission. It is measured as (\(\frac{\text{Pitch circle diameter (reference diameter)}}{\text{Number of teeth}}\)).

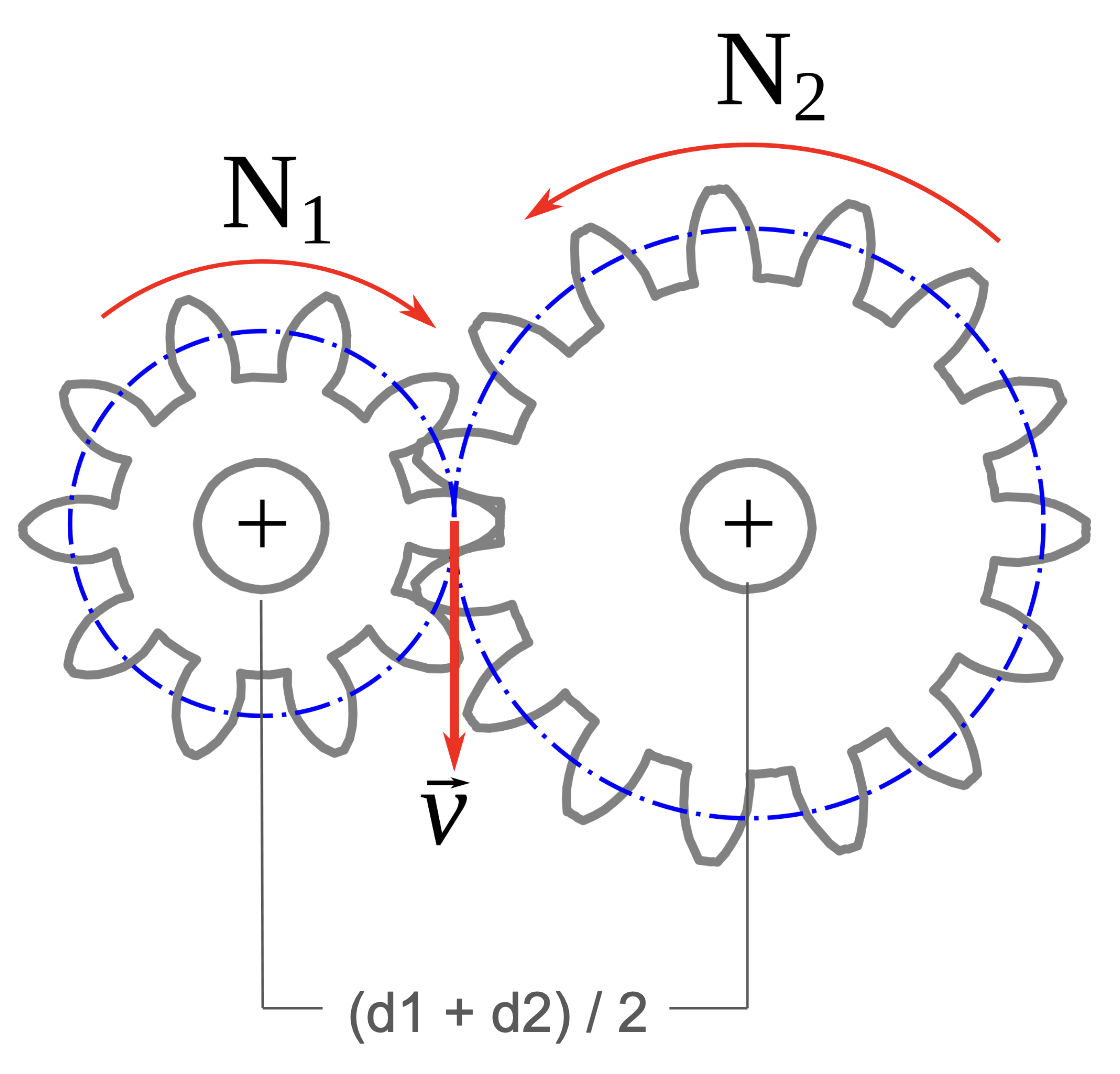

Gear Train

And let’s not overlook the gear train – a veritable circus of spinning cogs, where proper module and pressure angle matchmaking is key to avoiding the dreaded “backlash”.

To make gears work,

- All gears in contact must have the same module and pressure angle.

- The spacing between two gears must be the average of their reference diameters.

Gear ratios, the secret language of these mechanical marvels, allow us to manipulate speed and torque like puppet masters. The magic formula?

where:

- \(d =\) Reference diameter

- \(N_{\text{teeth}} =\) Number of teeth

- \(\omega =\) Angular speed

- \(\tau =\) Torque

Backlash

Backlash is the clearance or play between the mating teeth of gears. It can cause issues like vibration, noise, and inaccurate positioning. To minimize backlash:

- Use gears with precise, tight tolerances on the teeth.

- Adjust the center distance between gears to eliminate excess clearance.

- Employ pre-loaded gear arrangements, such as using spring-loaded idler gears.

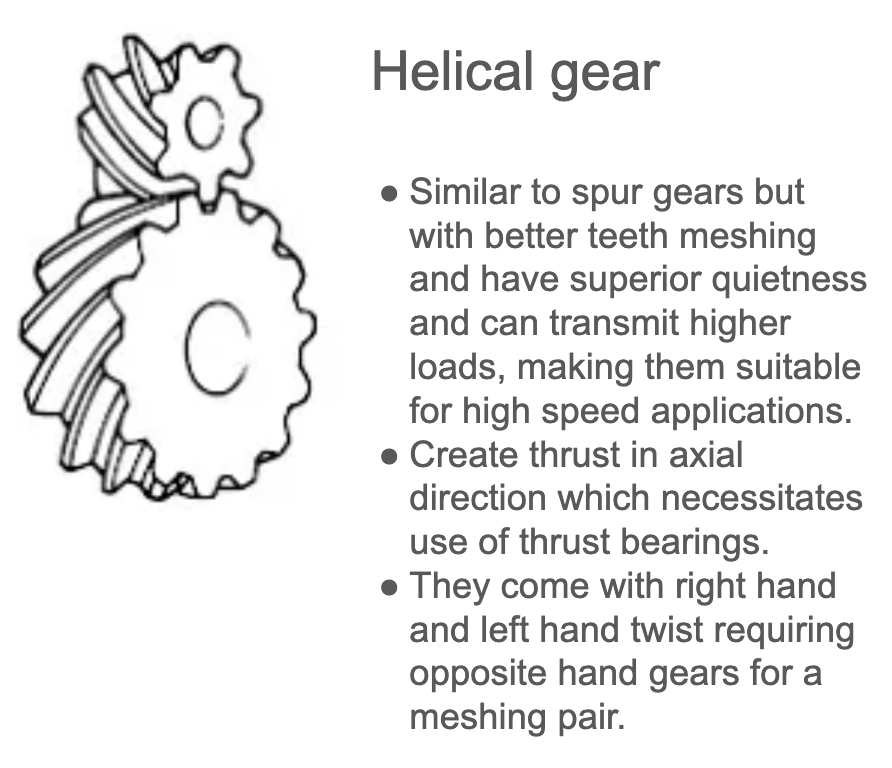

- Use helical gears instead of spur gears, as the angled teeth help reduce backlash.

- Increase the number of teeth on the gears to distribute the load.

- Maintain proper lubrication to reduce wear and tear.

So there you have it, folks – the secret lives of gears, where the tiniest of teeth can make a world of difference. Next time you hear the whir of machinery, take a moment to appreciate these unsung heroes, quietly doing their gear-y duty.

References

[1] Types of Gear. Available at: https://khkgears.net/new/gear_knowledge/introduction_to_gears/types_of_gears.html (Accessed: 24 January 2025).

[2] Spur Gear Calculator and Generator. Available at: https://www.engineersedge.com/calculators/spur_gear_calculator_and_generator_15506.htm (Accessed: 24 January 2025).

[3] Gear train Available at: https://en.wikipedia.org/wiki/Gear_train (Accessed: 24 January 2025).

Enjoy Reading This Article?

Here are some more articles you might like to read next: